|

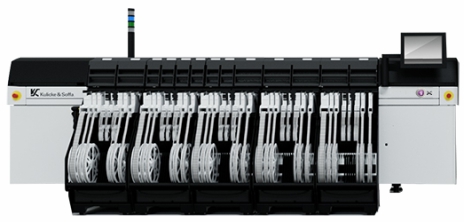

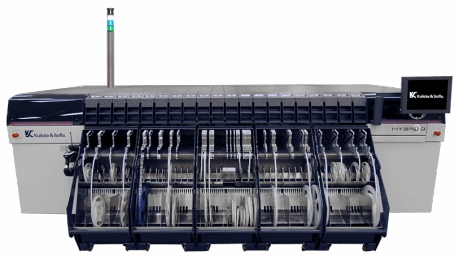

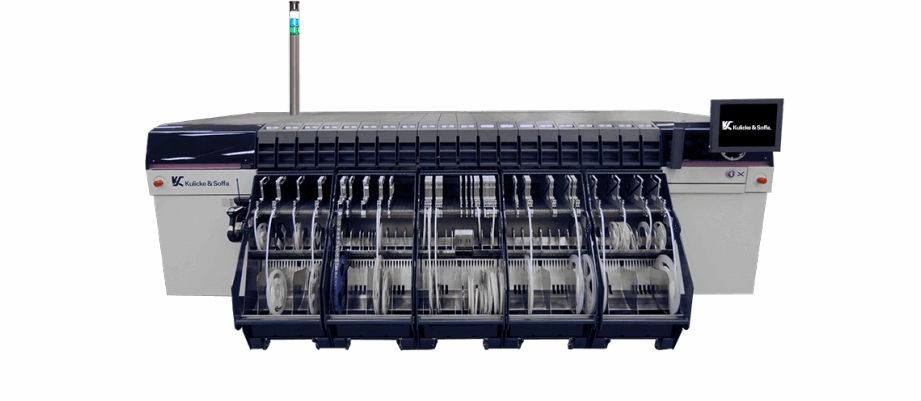

The new iX has continuous enhancements in the total pick and place process, further introducing a new light weight feeding range with proven high field-measured pick-rates of over 99.99%, higher placement accuracies for passives (35 microns), new component range, 25% increased output for camera aligned components. iX continues the success of the former A-series platform – arrived by now to maturity. This platform provides unique performances in the industry, like industry’s most controlled placement process or reliability <1 DPM.

In short, the iX502/302, iX 302 offer:

• A complete and modular range, to handle more and a wider variety of components, for any application and production line

• Higher yield, capacity and reliability, with faster changeover and ramp-up times.

• Advanced PCB collision detection mechanism ('when does the component touch the board')

• No impact force = No component cracking

• Real-time closed-loop placement force control to place the part at the specified placment force

• Placement process verification (according blue-print value) - Always check the reliablilty of each individual placement

• PCB surface mapping allows all other placement heads to place without impact on the learned placement height.

• Capacity can be added or removed in order to increase or decrease output without altering the line footprint: True capacity on demand

|